TubesontheWeb.Com

Section I: General Precautions

This unit uses potentially hazardous

voltages. During testing, these voltages are present on exposed

terminals. Do not touch any tube socket or jumper while testing is in

progress, especially if any buttons are depressed.

The control box gets rather hot in certain areas

after prolonged use. This is normal. Turn the unit off when not in

use.

The sequence of what gets turned on or off first

is not critical. There is one exception. Do not turn the control

box on if the program is already running and a test has been started.

Exit the test first.

This unit is user programmable. It is

possible to program tests that can destroy a tube. TubesontheWeb.Com,

LLC, assumes no responsibility or liability for the misuse of this product.

Section II: Initial

Setup

After unpacking, set up the unit near the computer

system to be used. The computer should meet the following minimum

requirements:

- Any PC Compatible computer

- 640K Ram

- USB port OR 3.5" diskette drive

- Parallel port

- Keyboard

- Monitor

- For best results a Pentium II or better and a color

monitor are recommended

- For printing curves a computer running Windows and

Microsoft Excel must be available

Getting started is easy. Just connect the supplied cable

from your computer's parallel port to the control box. If using the

floppy disk, load the software by running the setup.exe program that comes on

the floppy disk supplied with your unit. To run this program on a DOS computer,

insert the disk, then type A:SETUP at the DOS

prompt. On a Windows 95 or newer system, click on Start, then select Run. In the box that pops up, type A:SETUP and click OK. The setup program then guides you

through loading the software on your system. If using the USB stick, set your

computer to boot from the USB port. If your computer does not support booting

from USB drives, you can copy the tube tester software from the USB stick to

your hard drive.

The software defaults to using parallel port LPT1

on your computer, which is usually addressed at 378 hex.

This is the most common configuration on computers that have only one parallel

port. If the port you connected the control box to is at a different

address, you will need to enter this address during the software

installation. Valid addresses are 378, 278, and 3BC. If you are not

sure, just select the default. This setting can be changed at any time by

accessing the System Test Menu.

Be sure to connect the short jumper to the plate

current meter jacks. The unit will not work without it.

Once the software is installed, there is a one time setup procedure that should be performed.

This procedure sets the tester to match your AC line voltage. To perform

this procedure now, do the following:

- Turn on the tester and the control box.

- Launch the software by double clicking on the icon, or

by typing "TT" at the DOS prompt. This should take you to

the Search Screen.

- Type in "TEST12" for the tube number.

This will bring up the Filament Standard Adjust test. Open the

hinged cover on the right side of the tester.

- Type "T" to start the test, then press the "Filament Std. Adj."

button. Use the "Filament Std. Adj." control to adjust the

meter reading to half scale.

- Press ESC to exit the test.

- The tester is now calibrated to your line voltage, and

probably will not need any further adjustments unless your line voltage

varies a lot.

NOTE: The software automatically selects the proper filament

voltage for each tube, based on its current draw. It is no longer

necessary nor desirable to perform the filament

standard adjustment for each tube. If you do want to check it, do it

before the tube is inserted.

Section III: Software

Navigation

The software is easy to use and generally self explanatory. However, a few pointers about

keyboard commands are in order:

- Press ENTER or Down Arrow to get to the next field.

- Press Up Arrow to get to a

previous field.

- Pressing Insert toggles between insert and type over

modes.

- To skip remaining fields and jump directly to the

bottom of the page, press Page Down.

- The ESC key always takes you back to where you came

from or to the Main Menu.

Section IV: Menus

The Main Menu has six selections:

(0) - Exit

- This selection exits the program completely.

Pressing ESC while at the Main Menu does the same thing.

(1) - Test Tubes

- This selection takes you to the Search Screen so that

you can enter the number of the tube to be tested.

- You can enter a partial number if you wish. For

example, entering 12AX will bring up 12AX3.

- Press ENTER to skip the first field. This allows

you to enter the number in the Power Search field.

- Use the Power Search field to search both the Type and

Alternate Number fields.

- Use Power Search to search inside type numbers.

For example, entering AX will match 12AX3, 6AX8, CK533AX, etc.

(2) - Add Custom Test

- Use this selection to program and store your own tests.

- Both Transconductance and

Plate Current tests can be programmed.

(3) - Calibrate Tester

- This selection can be used to put the tester through

the complete calibration sequence.

- Calibration instructions are printed on the screen as

you go.

- This selection is also used to calibrate filament

voltages.

(4) - Re-index Data Files

- Use this selection if you suspect any sort of data

corruption. For example, you can't find a certain test that you know

is there.

(5) - System Test Menu

- This selection allows you to check relays and wiring in

various ways.

- This is also where you can set the address of the parallel

port in your computer.

Many of these selections are discussed in more detail in other

sections of this manual.

Section V: Testing Tubes

This section assumes you have inserted a tube and

have called up a test. Most of the following information can be found in

the tube tester's original manual, but is repeated here for convenience.

Tube testing is a three step process for most

tubes. The tester's buttons and meter scales are labeled 1, 2, and 3 to

correspond to these tests. For the purposes of this discussion we will

assume a tube is already inserted and the test started at the computer.

Never forget when calling up a tube to make sure you really are on the right

tube. Also note whether or not there are any special instructions.

Then press the "T" key to start the tests.

Step 1: Shorts and Leakage

Just below the meter there is a metal hood which

shades 5 neon lamps. These are the shorts indicators, and are the first

thing you should check. They become active as soon as the test is started

at the computer, you don't have to press any buttons on the tester. If

any of these lamps are flickering or glowing, then an inter-element short in

the tube is indicated and the tube should be considered bad. Do not press

any buttons and do not continue testing if any of the shorts indicators are

glowing.

If you want to perform a more sensitive grid

shorts test, open the hinged door on the right side of the tester and press the

"Sensitive Grid Shorts" button. It is a good idea to just get

in the habit of performing this test, especially on audio tubes. It will

cause the grid shorts lamp to glow if the tube has even an extremely small

leakage path to the control grid.

Now observe the meter. With no buttons

depressed, the meter is indicating the heater to cathode leakage. We are

on step one, so we read the top meter scale, appropriately labeled with a

"1". If the reading is not within the green area on the top

meter scale, then the heater to cathode leakage current is excessive.

This completes the shorts and leakage tests.

Step 2: Quality Test

The quality test is performed simply by pressing

button "2" and reading meter scale "2". The meter

indicates the tube's "quality". Anything above half scale is

passing, anything below that is failing. You can consult the computer

screen to convert this reading directly to uMhos or

mA. If the test is a transconductance (uMho) test, you can make sure you are getting a very

accurate reading by pressing the "Grid Sig. Off" button. Again

this button is under the hinged cover on the right side of the tester.

This should make the meter drop to zero, indicating a perfectly balanced Gm

bridge measuring circuit. If the reading is something other than zero,

you can use the Gm Balance controls to null the meter to zero.

As a part of the quality test, you may wish to

perform the cathode activity test. Press the "Cath. Act."

button. This reduces the heater voltage by 10%. If after 1-1/2

minutes the reading has dropped by more than 10% of the tube's normal reading,

then the tube should be rejected.

Sometimes the shorts lamps may flicker or glow

during the quality test. This is normal. The only time you should

pay attention to the shorts indicators is when button "2" is not

pressed.

Step 3: Gas Test

The last step is the gas test. Press button

"3" to perform this test, and read meter scale "3".

If the tube is excessively gassy, the meter will deflect above the green area.

The tests are complete unless the lamp next to

button "4" is lit. This indicates a dual section in the tube

that can be tested with a single test. Simply perform all the tests

twice, once with button "4" held down, once without.

If there are no other tests programmed for this

tube, you are done. The computer screen will indicate how many tests are

involved for this tube (it could be anywhere from 1 to 6 tests) and which test

you are currently on. To end this test and/or go to the next test,

release all buttons and press the space bar. Please do not press the

space bar (or ESC) before releasing buttons "2" or "3".

Section VI: Software

Overview

This section will take us step by step through

calling up a tube, testing it, creating a custom test, and setting up a curve

trace. Please follow along on your computer.

When the software is launched, the Search Screen

is the first screen we see.

Simply type the number of the tube to be tested

into the upper field (fields are areas which you can type in and they are

always blue) and then press ENTER. If desired a partial number may be

entered. The lower field, Power Search, is

used to search the database more thoroughly and also lets us use the program as

a cross reference (more on this later).

Type in KT66 and press ENTER. Check out the

screen we are presented with. Whoa! There is a lot of information

there, but don't let that scare you. In fact, if all we wanted to do is

test this tube, we wouldn't be concerned with anything on this screen except to

confirm that we have pulled up the right tube and the number of tests involved.

We could simply press the "T" key (for Test) and we are

testing. Now that's fast! At this point the tester is operating

just like we had inserted the KT66 test card. We complete the testing

procedure just like we normally would on any Cardmatic:

1) - Check for shorts by observing the tester's

short lamps, and read the meter to check for any heater to cathode leakage

2) - Perform the quality test (press button 2 and read the meter)

3) - Perform the gas test (press button 3 and read the meter)

That's it! It really is that easy to

use. If we wish, we can convert the meter reading obtained during the

quality test directly to uMhos by consulting the

color coded meter conversion chart on the right side of the screen. If

the tube has more than one test, we press the space bar to take us to the next

test. Pressing ESC takes us back to the search screen and we are ready to

test the next tube. If all you want to do is test tubes, you are

done. But, if you want to do more, read on.

The rest of the information on the screen is there

only if we need it (or are curious). For example, after studying the test

parameters we may decide that for our application a more accurate test could be

accomplished if we changed the conditions under which the tube is being tested.

To achieve this, we can easily add a test to the database that uses our

parameters. Lets do

that by pressing ESC to return to the search screen, then pressing ESC again to

get to the Main Menu (pressing ESC from anywhere always takes us back).

There are several options. For now, lets just select item 2, "Add

Custom Test", so we can input our modified KT66 custom test.

Since we will still be testing a KT66, we should

answer this first question "Yes" and tell it to read the data from

the KT66 already in the database. That way things

like the type of test, pin out, and filament voltage are already properly set

for us. If this question is answered "No", then we could change

things like the type of test (Transconductance or

Plate Current) and bias mode (grid or self). For now answer yes, then

KT66 for the tube to read the data from.

In this case we are looking at a Transconductance test using grid bias. What we decide

to change is the plate voltage. We are going to set it at 180V.

Unfortunately we can't go much higher because we start to run into the limits

on the amount of current we can draw from the regulated B+ power supply.

We will also need to increase (make more negative) our negative grid bias to

keep the tube's operating point within the proper range for the gm measurement

bridge circuit.

We start by giving it a name like KT66Spl (for

KT66 Special) and changing the parameters just mentioned. When we have

filled in all the fields and reached the bottom of the screen, the program asks

us to confirm our changes. After pressing the "Y" key, it then

stores our test in the database along with all the other tests. The

original KT66 test is still there too, untouched. Now go back to the

search screen, pull up KT66Spl, and lets

look at it in more detail.

First we will discuss at the upper section on the

screen. It contains three fields of information that we can edit if we

wish: the type number, an optional alternate number, and a place for

remarks. The type number is simply the number that the tube is known

as. The alternate number is used when a tube is also known by second

number. For example, the 6BQ5 is also known as an EL84. This

alternate number field is included in the search when using the Power Search

that we mentioned earlier, which is how the program functions as a handy cross

reference. Next, the remarks field is used anything we might need to

know. For example, a test might be one that measures a tube's ability to

achieve complete cut off, and any reading under 50 on the meter indicates a

good tube. In that case the remarks field will say "OK UNDER

50", so pay attention to this field. We can add to it anything we

like, but please do not change anything that is already in this field.

The upper section also shows the total number of tests involved for this tube

and which test we are currently on.

The right side of the screen holds the meter

conversion chart. In this case it is a transconductance

test so we can convert the meter reading directly to micromhos

by consulting this chart. If this were a current or voltage test, the

chart would convert directly to mA or volts for us. The chart is color

coded: good tubes will register in green numbers, marginal in yellow, and

failing in red. It is a sliding chart that adjusts automatically to match

the test. At the bottom of the chart there is a notice that the letter

"O" key (stands for Odd/Even) can be pressed at any time to toggle

the chart between odd and even numbers.

The left side of the screen shows what tester line

is connected to what tube pin. This is worded as "tester lines"

intentionally because these lines are not always

used for what they seem. The tester circuit is so versatile that it is

sometimes handy to use a line for something other than what it is labeled

as. Do not design your circuits using the pin out shown on this screen!

The central area of the screen shows the test

parameters. Some of these fields change depending of the type of test

being performed. In this case most of the parameter fields can be edited,

or changed, because this is our custom KT66

Special test that we added earlier. These fields cannot be changed in the

3800+ tests that come with the tester. Of particular interest is the

"Adjusted Filament Voltage" field. This is the voltage actually

being chosen from the filament transformer taps, and is based on the amount of

filament current being drawn. It makes up for the voltage drop in the

wiring so that the tube receives the proper filament voltage at the pins.

Low filament voltage, especially on low voltage high current tubes, has always

been this tester's biggest weakness. This problem has been completely

eradicated since the computer picks the right voltage automatically!

At the bottom of the screen are the commands we

can use. They are all one key commands, so all we need to press is the

key indicated in the parentheses. Let's take a look at each, in

order. The first, (C)urves,

is discussed in the next section. The next command, (D)elete, is pretty much self

explanatory, and appears only on custom tests. None of the tests

that originally come in the tester's database can be deleted.

Next, (E)dit,

is used to change any fields on the screen that are allowed to be changed and

is very simple. When the "E" key is

pressed, the cursor moves up to the top field. Make any changes needed

using normal editing keys (delete, insert, etc.). Use ENTER or the down

arrow key to skip any fields that do not need changes. Use the up arrow

key to get back to a previous field. After making changes, either press

ENTER repeatedly to get to the bottom of the screen, or press Page Down to skip

the remaining fields. If one or the other isn't done, or ESC is pressed

after making changes, then the changes will not be saved.

The (I)nstructions

command is needed only if you have not read this document. Pressing the

"I" key in this case will give us only generic instructions that we

have already covered. On the other hand, if there are instructions that

are specific for the tube being tested (such as most voltage regulator tubes),

then the instructions will automatically pop up in the central area of the

screen when you first call up that tube. For example, pull up 0A2 and

look at the test screen. As you can see, the parameters that are normally

presented in the central part of the screen has been

replaced with instructions specific for this test. Also a new command, (D)etails, has appeared that can be

used to switch from the instructions to the parameter display that is supposed

to be in the central screen area.

The next command, (R)elays, is a screen that shows which switches

(relays) are closed for this test, and a graphical representation of the card,

if we cared. This screen is only used for diagnostic functions.

The all important (T)est command is next. Simply

insert the tube into the tester and press the "T" key to start the

test.

The rest of the commands are simply (Q)uit, which exits the program

completely, and representations of the left and right arrow keys, (<) and

(>), which lets us quickly move backward and forward through the tube

database in numerical order. For example, to bring up our KT66Spl test,

we could just type KT66. When the KT66 test screen (the original one)

comes up, pressing the right arrow key makes the program go to the next test,

which in numerical order would be the KT66Spl test we are looking for.

Section VII: Curve

Tracing

First, we will be going through the process of

setting up the curve test parameters for our newly added KT66 Special, but

don't get confused here. The set up procedure we are getting ready to

discuss can be tedious, but once completed the process of creating the curve

charts themselves is quick and easy (much easier than

the initial setup procedure). Here is a quick overview of the curve trace

process, once the parameters have been set up:

- Pull up the tube to be tested, just like you normally

would.

- Press the "C" key to bring up the curve trace

test screen.

- Insert the tube and press the "S" key to

start the tests.

- After allowing the tube to warm up, press button 2 and

note the meter reading. Release button 2.

- Press the space bar. The program prompts you to enter

the meter reading then moves on to the next test.

- After all the tests are completed, the program stores the

data in a file that can be read by Microsoft Excel.

- The file is opened in Excel for display and/or

printing.

Excel macros are provided on the program disk that automates the

process of displaying and/or printing the curves.

To look at these steps in detail, we will start

with our KT66 Special that we already have pulled up on the screen.

Again, please follow along on your computer, or none of this will make sense.

When we press the "C" key, one of two

things will happen. Normally, a tube will already have had its curve test

parameters entered, in which case the program will take us directly to the

curve trace test screen. However, these parameters have not yet been set

up for our KT66Spl, so when we press the "C" key we are taken to the

curve setup screen.

Hopefully, to save time, there will be other tubes

with similar characteristics that already have their curve parameters

set. If so, we can read the default data in from one of them.

Setting up a good curve is usually a process of trial and error.

Fortunately, once a curve is set up for a particular tube it is stored in the

database. Most common audio tubes already have the curve test parameters

set up. But for now we are going to answer "No" to this

question and setup a curve from scratch. This takes us to the first part

of the setup process, the tube's pin out.

Remember the program can only guess at the

pinout. Even though most of the time it will be right, it is important to

consult a tube manual or schematic at this point to verify that the pin out is

correct. After making sure it is correct and/or making any necessary

changes, we can continue to the next part of the curve setup process, selecting

the plate voltage.

Our choices range from 10 volts to 260

volts. A chart is presented that shows the current limit of the B+ supply

for any given voltage. As you can see the maximum available current peaks

at 150 volts, which is why 150 is the most common plate voltage used for

testing. You can exceed these limits by about 20% before the B+ regulation

starts to suffer appreciably. We decide to try a plate voltage of 180

volts. Now, for the last part of the set up process, we need to enter the

starting grid bias voltage and the amount to increment this voltage for each

test.

This is the toughest part to decide on. Use

your best judgment based on your experience with the characteristics of the

tube type being set up and the plate voltage you selected. If you don't

have any experience, don't worry about it, because you will almost certainly have

to tweak the values later anyway. In this case we are going to enter a

starting voltage of -16 volts, and a voltage increment of 1 volt per test (more

on why we picked these values later). After entering these initial values

we are now finished setting up the curve parameters for this tube. The

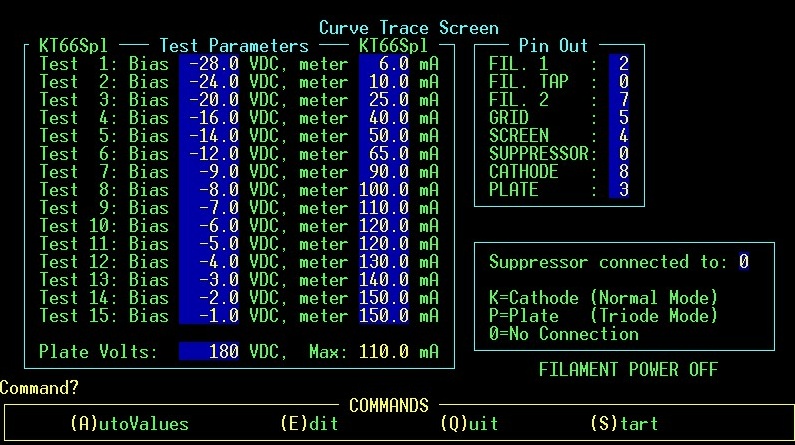

program automatically takes us to the curve trace test screen:

Actually, the screen you see here has already been

edited with the final values decided upon by using a trial and error

method. That is why we don't see the bias for the first test starting at

-16 volts and proceeding with 1 volt increments like we specified on the set up

screen. Since tubes are not very linear near cutoff, all properly set up

curves have relatively large grid voltage increments for the first several

steps. As you can see, most of the grid bias voltage increments really

are 1 volt apart once we get several steps into the tests. When setting

up new curves, pick a starting bias voltage based upon where you want the last

test's bias voltage to be, not on where the first test will actually

begin. In this case it was decided to have the last test's bias at -1

volt. Since there are 15 tests and the voltage increment is 1 volt, we

started at -16 volts. This resulted in the last test being at -1 volts

(-16 + 15 = -1). Note that not all curves need to be set up using all 15

tests, but the more we use the more accurate the results. Most tubes need

around 12 tests.

Notice there is an option for where to connect the

suppressor grid. If we are testing a pentode, we can connect it to either

the cathode (normal connection) or the plate (triode connection). If we

wished to change this setting we would use the (E)dit command to do so. The printed chart will

indicate whether the curve was done in normal mode or triode mode. The

screen grid, if applicable, is always connected to the plate during these

tests.

Lets quickly look at the commands available at the bottom of

the screen. First is (A)utoValues,

which simply allows us to choose a different starting bias and/or increment

voltage and then fills in the fields with these new values. Use it to

save typing if the bias values are so far off that they all need to be

changed. Next is (E)dit,

which will allow any setting on the screen to be changed. (Q)uit takes us out of the curve

trace test screen and back to the normal test screen (pressing ESC does the

same thing). Finally, (S)tart actually starts

the series of tests. Lets

press the "S" key see what happens.

Notice that the meter conversion chart is

back. It is not really necessary, but we can use it to tell how much B+

current we are drawing for the particular test we are on. The numbers in

the meter conversion section will turn yellow once the B+ power supply's rated

current has been reached. They will turn red once 120% of the rated current has

been reached. If we reach the red numbers, then the meter readings cannot

be trusted and we will need to edit the curve parameters to reduce the amount

of B+ current being drawn.

Now that we finally have the curve tests underway

we simply press button 2, note the meter reading, release button 2, then press the space bar. The program will ask us to

enter the meter reading before moving on to the next test. If we need to

go back to a previous test for some reason, we can press the BACKSPACE

key. It is easy to tell which test we are on because it is highlighted in

yellow and has the applied grid bias voltage printed to the right. This

procedure is repeated until all the tests have been performed.

If at any time during this procedure we need to

change the parameters of the test we are currently on (which we will since this

is the first time this set of curve tests have been used and the meter

sensitivity settings will almost certainly be wrong), we can press the

"E" key. This will allow quick editing of the bias voltage

and/or the meter sensitivity of the current test only. When setting the

meter sensitivity, it is recommended that a value be selected that results in a

meter reading of between 50 and 70 for a typical tube. This gives an

accurate current measurement while providing enough meter scale leeway to allow

for unusually strong tubes.

Once all the tests have been completed, the

program will ask to save the data. When told "Yes", the program

will prompt us with the tube's serial number. This is simply a sequential

number used to identify individual tubes. It is also the name given to

the file that the curve data is stored in. The computer will

automatically increment and remember this number, so we can just press ENTER to

accept the number the computer assigns. We also need to mark the tube

itself with this number.

The last question we are asked is where to save

this data file. If the program is being run on the same computer that

will be used to print the curves, meaning that it is a Windows based computer

that has MicroSoft Excel loaded, then it is

recommended to save the data files in C:\MYDOCU~1\ (the way DOS sees the

C:\My Documents\ folder). This is because the Excel macros look for the

files there. If the files need to be transferred to a different computer

for display and/or printing, then save them to a floppy disk (A:\). The program remembers where the last file was

stored, so after telling it the proper location once we can just press ENTER to

accept the default in the future.

During this whole procedure of editing and testing

the filament power was always on. This allows for quickly moving through

the tests since no warm up time is needed between tests. The filament

power is not removed until either the tests are successfully completed and the

data stored or the curve trace screen is exited. There is a prompt

displayed on the lower right portion of the screen that shows at any given time

whether or not the filament is powered.

We are now through curve tracing this tube, and

can move on to the next tube. We can do as many as we like in one setting

even if we are storing them on a floppy disk (the files are very small).

Once you get the hang of it you can create curves for a lot of tubes in a short

time. The macro that prints these curves will print all of them with just

one keystroke.

Section VIII: Setting up

MicroSoft Excel for Printing

Curves

This procedure gets the macros used for displaying

and printing curves ready to use. It consists of opening the macros in a

text editor such as Notepad, then cutting and pasting into Excel. This

needs to be performed only once, and is done on the computer that will be used

to print curves, which is not necessarily the same computer that is running the

tube tester software. Step by step instructions follow.

- Insert the original software disk in drive A:

- Open Excel

- Open Notepad (Start -> Programs -> Accessories

-> Notepad)

- Click on File -> Open

- Click on the "Look in" box, and select A:

- Click on Dispcurv.txt

- Click on Open

- Click on Edit -> Select All

- Click on Edit -> Cut

- Switch to Excel

- Click on Tools -> Macro -> Record New Macro

- In the Macro Name field, type DisplayCurve

- Assign a shortcut key if desired (Control-D is

recommended)

- Click on OK

- Click on Tools -> Macro -> Stop Recording

- Click on Tools -> Macro -> Macros

- Click on DisplayCurve then

click Edit

- Click on Edit -> Select All

- Click on Edit -> Paste

- Close Excel, answering YES to save changes (Do not skip

this step)

Now repeat the above procedure, this time using Princurv.txt in

place of Dispcurv.txt, and use Control-C for the shortcut key.

Section IX: Displaying

and Printing Curves

Printing curves requires that the files created by

the curve trace tests be stored in C:\My Documents. If you are using the

same computer for both testing and printing, then these files will already be

there. Otherwise, you need to manually copy them there. The easiest

way to do this is with Windows Explorer. The filenames all have an

extension of .csv.

Once you have the files in the My Documents

folder, open Excel. Use the following steps to display a single curve

test on the screen:

- Click on File -> Open

- Click on the "Files

of Type" box, and select Text Files

- Highlight the desired

file and click on Open

- Press Control-D

- Close this file and

answer NO to the save changes question before displaying another curve.

If you wish to print all the curves stored in My Documents,

simply press Control-C. Make sure your default printer setting in Windows

is correct first. Once you have printed all the curves, you will need to

either delete or move the .csv files out of the My Documents folder.

Section X: In Case of

Difficulty

The most commom problem

is forgetting to connect the jumper to the plate current meter jacks.

Always check this first.

Support is best obtained through email.

Quick and concise answers to problems can be obtained this way. Send

email to:

mrtube@tubesontheweb.com

You can also call during normal business hours,

although many times you might get a machine instead of a human. Email is

usually quicker, but if you wish to call the telephone number is 405-340-9062.

Be sure to check the web site FAQ for answers to

common questions. Program updates and fixes are there too. The web

site address is:

http://www.tubesontheweb.com

12-19-2004